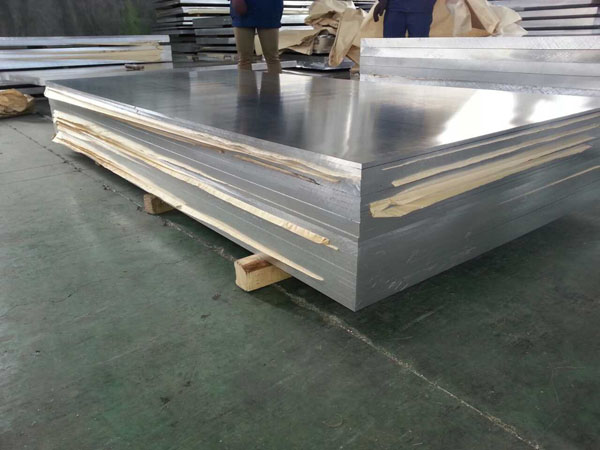

5086 aluminum plate

5086 aluminum plate has higher strength than 5052 plate and 5083 plate and its mechanical properties vary significantly with hardening and temperature. It is not strengthened by heat treatment; instead, it becomes stronger due to strain hardening or cold working of the material. This alloy can be readily welded, retaining most of its mechanical strength. The good results with welding and good corrosion properties in seawater make Alloy 5086 extremely popular in marine applications. It is also easy to form, stamp and weld.

Spot Sizes

5086 aluminum plate Thickness 4.5-220mm

Aluminum plate Physical Properties

| Alloy | Temper | Thickness mm | Tensile Strength Rm/Mpa Min. |

Yield Strength Rp0.2/Mpa Min. |

Elongation % Min. |

|---|---|---|---|---|---|

| 5086 | O / H111 | 6-12.5 | 240-310 | 100 | 17 |

| >12.5 | 240-310 | 100 | 16 | ||

| H112 | 6-12.5 | 250 | 105 | 8 | |

| 12.5-40 | 240 | 105 | 9 | ||

| >40 | 240 | 100 | 12 |

Chemical Composition % Max.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Each | Total | ||||||||||||

| 5086 | 0.40 | 0.50 | 0.10 | 0.20 -0.7 |

3.5 -4.5 |

0.05 -0.25 |

– | 0.25 | 0.15 | – | 0.05 | 0.15 | Remainder |

Aluminum Plate Typical Applications

5086 Aluminum Plate Typical uses: for applications that require a high corrosion resistance, good weldability and moderate-intensity situations, such as ships, cars and aircraft can be welded plates; the need for strict fire pressure vessels, refrigeration equipment, tower, equipment exploration equipment, transportation equipment, missile parts, armor and so on.

Haomei Aluminum Plate-We would like to highlight our aluminum plate,aluminum alloy plate 5083 aluminum plate,7075 t6 aluminum plate,aluminum 6061 plate,5086 aluminum plate,marine aluminum plate and aluminum mold plate with good quality and competitive price.we offers a wide range of aluminum Plate alloys for various applications.

Haomei Aluminum Plate-We would like to highlight our aluminum plate,aluminum alloy plate 5083 aluminum plate,7075 t6 aluminum plate,aluminum 6061 plate,5086 aluminum plate,marine aluminum plate and aluminum mold plate with good quality and competitive price.we offers a wide range of aluminum Plate alloys for various applications.